Steel rods are used everywhere. You find them in homes, bridges, machines, equipment and lots of different merchandise. They are strong, durable and long-lasting.

But no longer are all metal bars created equal. There is a wide variety of steel bars, each designed for a specific use.

In this easy guide, we will explain the different types of steel bars in simple words. This article is perfect for beginners, buyers, and anyone who wants clear information.

What Are Steel Bars?

Steel bars are long pieces of steel products. They usually are available in round, square, flat or hexagonal shapes.

Steel rods are used for:

guide constructing

make device elements

make gear

construct roads and bridges

Because steel may be very robust, it may withstand heavy masses and last for many years.

Why Are Different Types of Steel Bars Needed?

Different jobs require specific metallic bars. Some rods should be very sturdy. Some have to bend without difficulty. Some must oppose warfare.

This is why producers produce a wide range of steel bars for different needs.

Choosing the proper steel bar saves money and improves protection.

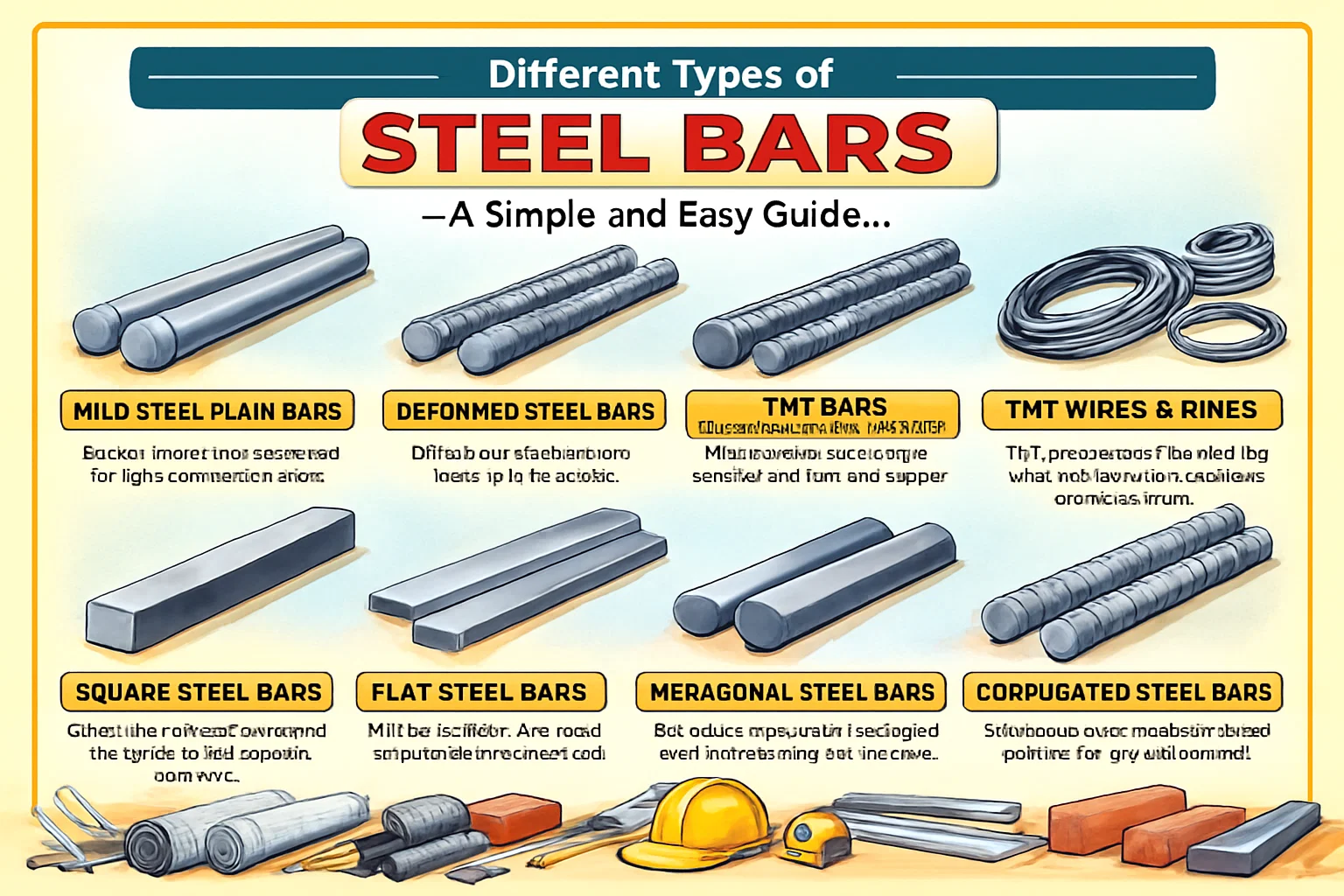

Main Types of Steel Bars

Let’s look at the most common types one by one.

1. Carbon Steel Bars

Carbon metal bars are the most widely used. These are made of iron and carbon.

The quantity of carbon determines how tough or smooth the steel is.

Features:

very strong

smooth to the system

value powerful

Usage:

production work

machine parts

axle and bolt

In simple words many builders and factories decide upon carbon steel bars because they are reliable and economical.

Also If you are looking for a High-Quality Carbon Steel bar supplier, always choose one that offers tested and certified materials.

2. Mild Steel Bars

Such as Mild steel bars are a type of low-carbon steel. And they are soft and easy to shape.

Features:

- Easy to weld

- Easy to cut

- Low cost

Uses:

- Construction frames

- Gates and grills

- General fabrication

Such as mild steel bars are perfect when strength and flexibility are both needed.

3. Deformed Steel Bars (Rebar)

In simple words, Deformed steel bars are also called reinforcement bars or rebars. And they have ribs on the surface.

These ribs help the bar grip concrete strongly.

Features:

- Strong bond with concrete

- High tensile strength

Uses:

- Buildings

- Bridges

- Roads

Such as Rebars make concrete structures safer and stronger.

4. Stainless Steel Bars

In simple words Stainless steel bars contain chromium. And this helps prevent rust and corrosion.

Features:

- Rust-resistant

- Clean surface

- Long life

Uses:

- Food industry

- Medical equipment

- Marine applications

Stainless steel rods cost more, but they last longer and look better.

5. Alloy metal rods

Alloy metallic bars are made by adding elements consisting of chromium, nickel or molybdenum.

These factors improve overall performance.

Features:

- Very strong

- Heat resistant

- Wear resistant

Uses:

- Automotive parts

- Heavy machines

- Industrial tools

Alloy steel bars are used when standard steel is not strong enough.

6. TMT Steel Bars

Such as TMT stands for Thermo-Mechanically Treated.

And these bars go through exceptional heating and cooling.

Features:

- High strength

- Good flexibility

- Earthquake resistant

Uses:

- Residential buildings

- High-rise structures

TMT bars are very popular in modern construction projects.

7. Square Steel Bars

Square steel bars have four equal sides.

Features:

- Good strength

- Easy to handle

Uses:

- Frames

- Grills

- Machine components

They are used when flat surfaces are needed.

8. Round Steel Bars

Round steel bars are circular in shape.

Features:

- Smooth surface

- Even strength

Uses:

- Shafts

- Fasteners

- Manufacturing parts

Round bars are standard in engineering work.

9. Flat Steel Bars

Flat steel bars are wide and thin.

Features:

- Easy to bend

- Good surface area

Uses:

- Brackets

- Frames

- Support plates

Such as They are used in both construction and manufacturing.

How to Choose the Right Steel Bar

Before buying a steel rod, ask these easy questions:

What is the benefit?

Do I need higher power?

Does it resist water or chemicals?

Is welding necessary?

If your project requires high-energy carbon steel, it’s a wise choice. For corrosion resistance, chrome steel is higher.

Always purchase from a dependable provider of excellent carbon steel rods to avoid first-class troubles.

Benefits of Using the Right Steel Bar

Choosing the right metal rod offers several advantages:

better security

lengthy life

low repair expenses

better overall performance

The wrong material can result in cracks, defects and additional expenses.

Steel bars are the backbone of construction and manufacturing. There are many forms of metallic bars, and each has its own role.

Conclusion

Carbon steel bars, moderate metallic bars, stainless steel bars and alloy metal bars all meet one-of-a-kind wishes. Understanding these sorts will assist you in making better decisions.

Always focus on nice. Work with a dependable provider. And select the metallic rod that satisfactorily fits your task.